Operational control and production and plants data collection

Manage the production activities through process, operators and machine data collection with simple and efficient monitoring and control tools to collect the right data at the right time.

Following the progress of production orders adding all the information required for process analysis and collecting the data of production lines and machine functioning allows to ensure lead times, thus preventing and correcting promptly what occurs in the production compartment.

Simple and intuitive monitoring tools enable control skills at all levels, so that every company feature has all the real-time insights required to guarantee the control and correct execution of the production process.

- OPERATIONAL CONTROL

- Orders loading at plants

- Production sequences

- Checking orders viability through materials control

- Real-time production progress reports

- Analysis of orders status

- Checking the state of plants

- Reports and dashboards of collected data analysis

- Operator instructions management

- Plants causes master data management

- Plant state dashboards and KPI display

- Plant analysis reports (downtime analysis, collected parameters history)

- Operator data collection (PDA)

- Declaration of production

- Operator checklist management

- Product and process data collection

- Production progress data collection

- Non conformity information collection

- Production times information collection

- Machine data collection

- Plant functioning parameters collection (produced quantities, productivity or speed, waste declaration alerts)

- Performance data collection (produced quantities, speed, performance)

- Plant downtime causes and information collection

- Setup data collection

- Alerts collection

- Paperless real-time view of all collected information minimizing errors due to paper management

- A single data container for all process information for more efficient decisions

- Greater control on the compliance of promise and estimated production times

- Greater control on the state of plants

- Greater process efficiency through the analysis of the history and inefficiencies due to down times and defects

- Real time integration among different bodies that have to analyze production data

- Automatic data collection process and removal of processes that lack added value

- Accurate assessment of production costs

- Absolute decreasing of potential errors due to information-related deficits

- Operators productivity increase

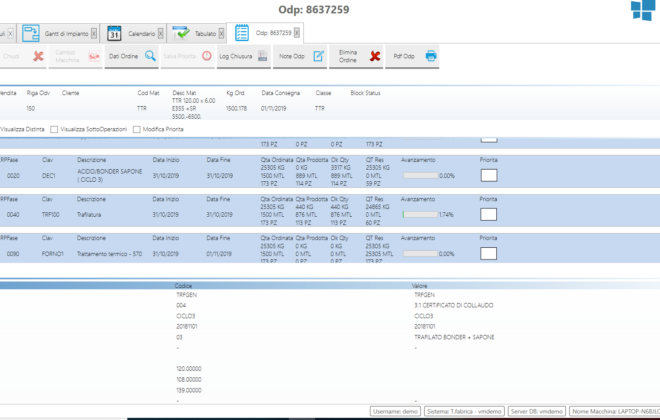

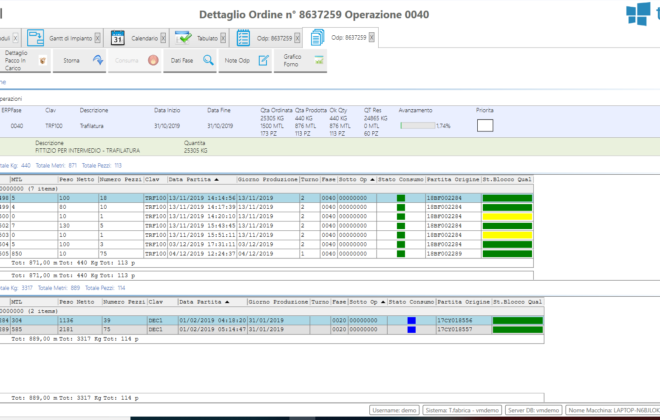

Detail of a production order and the progress of each single operation

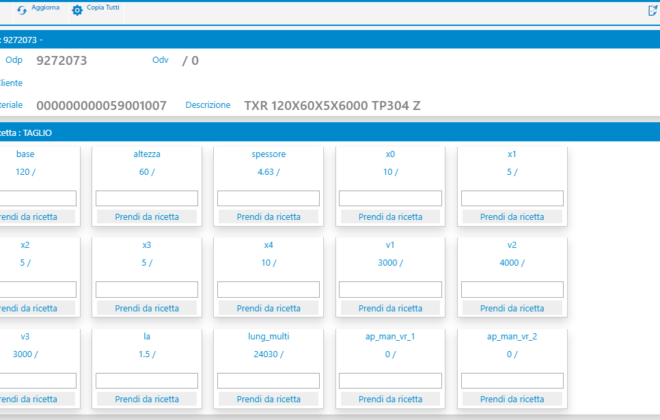

Example of recipe linked to the order being processed on the plant

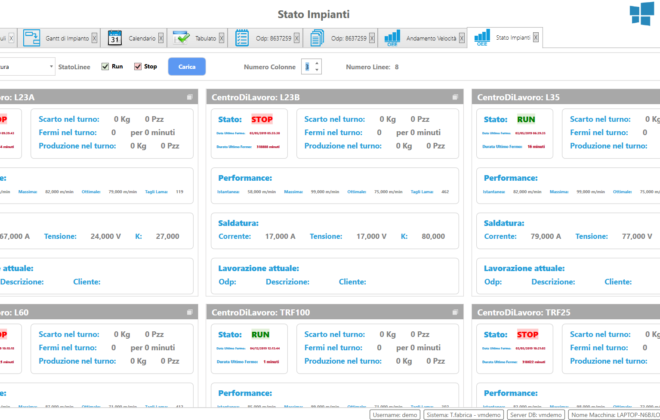

Display of the plants status with information on monitored parameters, production declarations and work in progress orders.

The detail of the single operation and the related production events